New Method Speeds Up Industrial Design Optimization

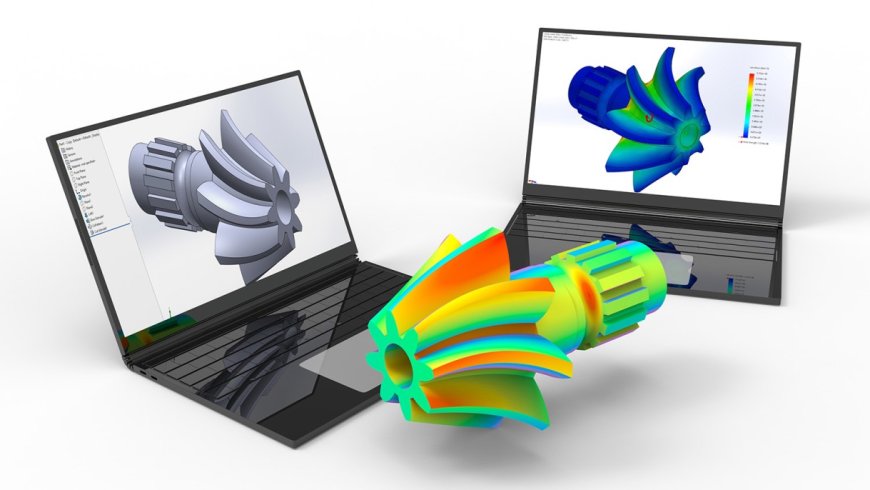

A research team has developed a faster and more stable approach to topology optimization for industrial design. This new method significantly reduces computational time, making it easier and more cost-effective to create complex designs with higher resolution. The team's innovative approach, called the SiMPL method, eliminates common optimization problems and can lead to up to 80% fewer iterations compared to traditional algorithms.

With the rise of 3D printing and advanced manufacturing, engineers can now build once-impossible structures. Topology optimization is a design strategy that maximizes material distribution for optimized designs.

A research team from Brown University, Lawrence Livermore National Laboratory, and Simula Research Laboratory has improved the speed and stability of topology optimization algorithms. Their work was detailed in two papers published in the SIAM Journal on Optimization and Structural and Multidisciplinary Optimization.

The team's method is more efficient, enabling quicker and cheaper designs or more complex designs with higher resolution. Topology optimization is like painting in 3D, starting with a blank canvas and using a computer to distribute material for optimal performance.

The iterative process involves updating material patterns until the design maximizes structural properties with minimal material. The team's new SiMPL method optimizes the optimization algorithm itself, reducing the number of iterations needed for a final design.

SiMPL eliminates impossible solutions, transforming the material space to streamline the process. Benchmark tests show up to 80% fewer iterations are required, significantly reducing computing time and making topology optimization more accessible.

The team has made the algorithm freely available for engineers and researchers to use, simplifying complex mathematical theory into a few lines of code.

According to the source: Mirage News.

What's Your Reaction?

Like

0

Like

0

Dislike

0

Dislike

0

Love

0

Love

0

Funny

0

Funny

0

Angry

0

Angry

0

Sad

0

Sad

0

Wow

0

Wow

0